Ring-expanding test of tubes

Ring-expanding test of tubes

A method for a ring-expanding test on tubes, that is used to reveal defects bothon the surfaces and within the tube wall by expanding the test piece using a conical mandrel until fracture occurs. It may be also used to assess the ability of tubes to undergo plastic deformation.

The ring-expanding test is applicable to tubes having an outside diameter from 18 mm up to and including 150 mm and wall thickness from 2 mm up to and including 16 mm.

Principle of Ring-expanding test

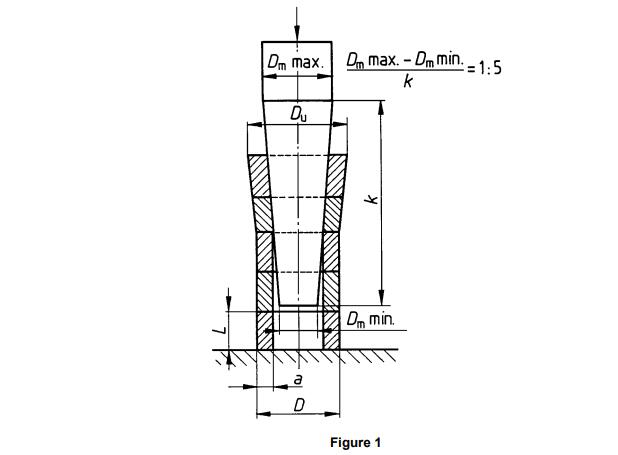

Expanding a ring cut from the end of a tube, over a conical mandrel until fracture, or until the expansion of the test piece reaches a value specified in the relevant product standard (see figure 1).

Apparatus

1.Variable-speed press or universal testing machine.

2.Conical mandrel, having a working length preferably tapered 1 : 5 as shown in figure 1, unless otherwise specified in the relevant product standard and its surface shall be of sufficient hardness, well-polished and free from scores.

Test piece

1.The length of the test piece shall be between 10 mm and 16 mm. Test pieces shall be taken from the ends of deburred tubes as manufactured before they are cut to length. The rings shall be cut so that the planes of the end faces are parallel with each other and perpendicular to the axis of the tube.

2.The edges of the test piece may be rounded by filing or chamfered by other methods.

NOTE — Non-rounded or non-chamfered edges are permissible, if the test result meets the test requirements.

3.When welded tubes are subjected to the test, the internal weld flash may be removed.

Procedure

1.In general, the test shall be carried out at ambient temperature within the limits of 10 °C to 35 °C. The test carried out under controlled conditions shall be made at a temperature of 23 °C ± 5 °C.

EN ISO 8495:2004 Licensed Copy: sheffieldun sheffieldun, na, Sun Nov 19 12:38:57 GMT+00:00 2006, Uncontrolled Copy, (c) BSI3

2. Before testing, the rings and the conical mandrel may be lubricated. Rings of the same size and the same type of metal may be placed one on top of each other. The rings and the conical mandrel shall be concentric (seefigure 1).

3.Force the conical mandrel into the rings until the required expansion is reached or the rings fracture.

4.The rate of penetration of the conical mandrel shall not exceed 30 mm/s.

5.The relative expansion shall be calculated in accordance with the relevant product standard.

6. Interpretation of the ring-expanding test shall be carried out in accordance with the requirements of the relevant product standard. When these requirements are not specified, the test piece shall be considered to have passed the test if no cracks are visible without the use of magnifying aids.

7 Test report

A test report shall be provided when so specified in the relevant product standard. In this case, the test report shall

include at least the following information:

a) reference to this International Standard, i.e. ISO 8495;

b) identification of the test piece;

c) dimensions of the test piece;

d) degree of expansion;

e) taper of the conical mandrel if different from that given in 4.2;

f) result of the test.